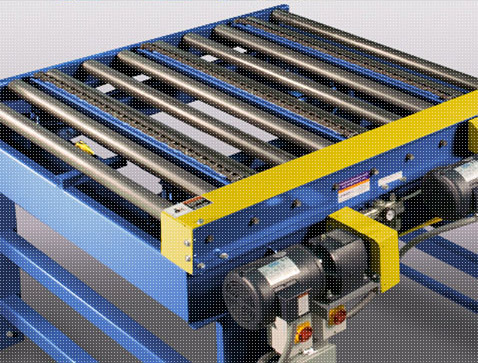

LEWCO, Inc. is a world-class, ISO 9001 certified, manufacturer of Industrial Ovens and Unit Handling Conveyors. Both product lines bring our value statement to market; Quality Products, On-Time, at a Competitive Price. LEWCO possesses the ability to easily customize industrial ovens and conveyors from a vast library of standard product designs to meet specific customer requirements thereby providing a custom solution at a cost effective price.